Mitchell Lewis & StaverMitchell Lewis & Staver

Engineering Pump Efficiency

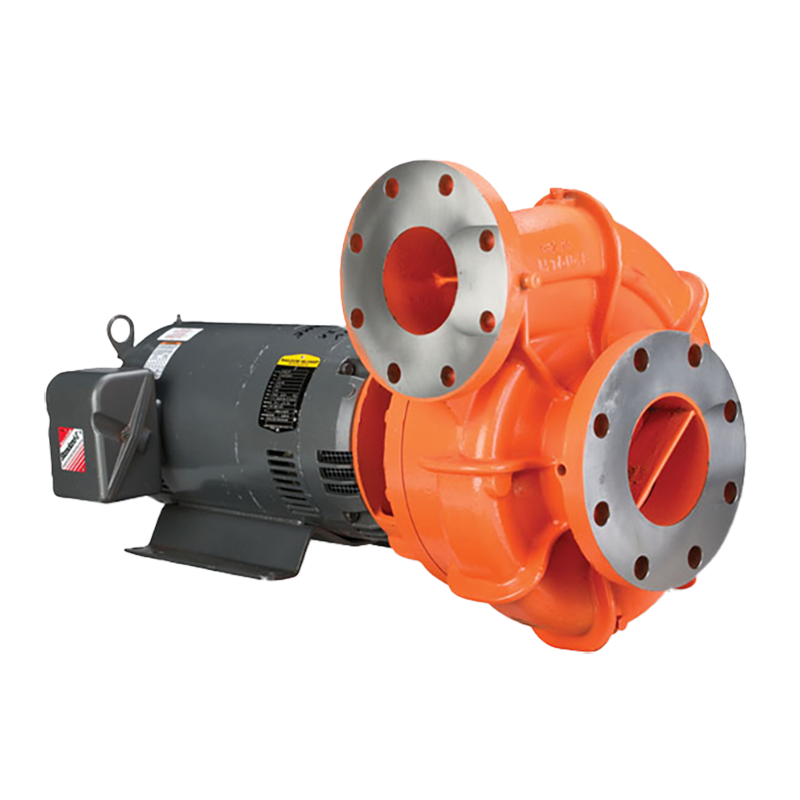

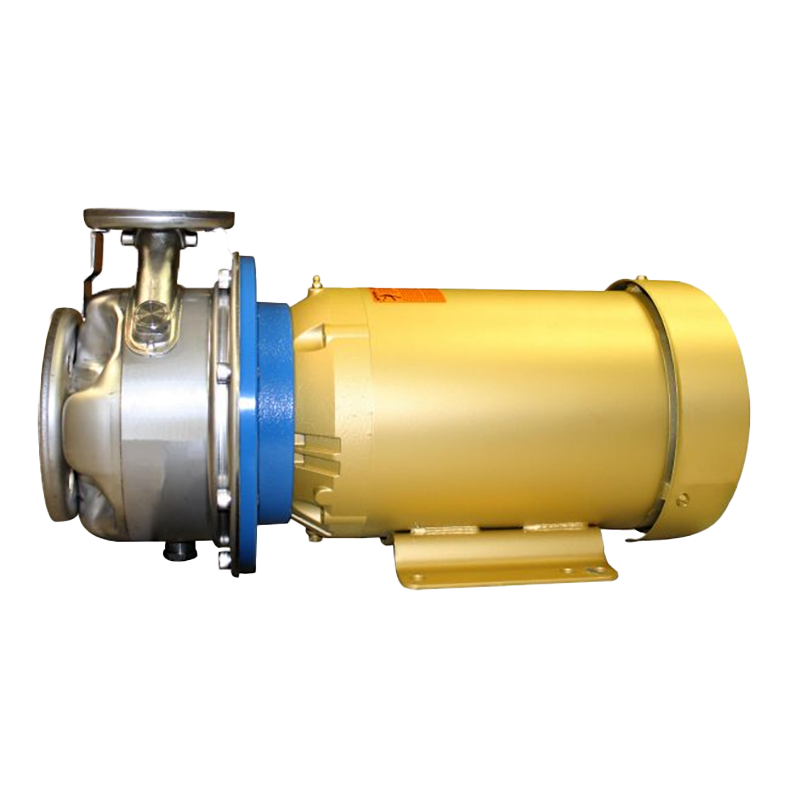

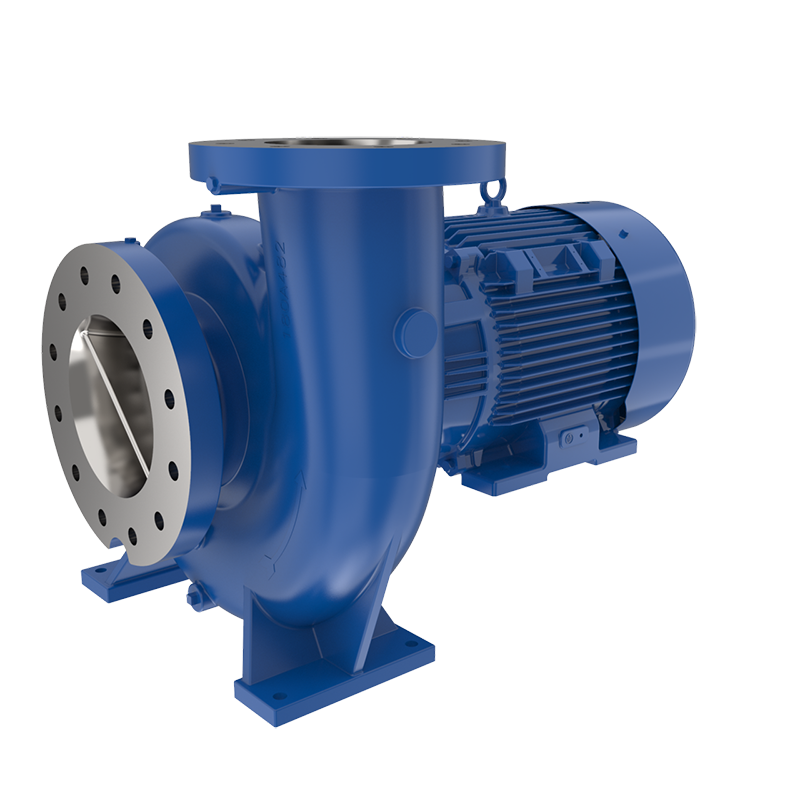

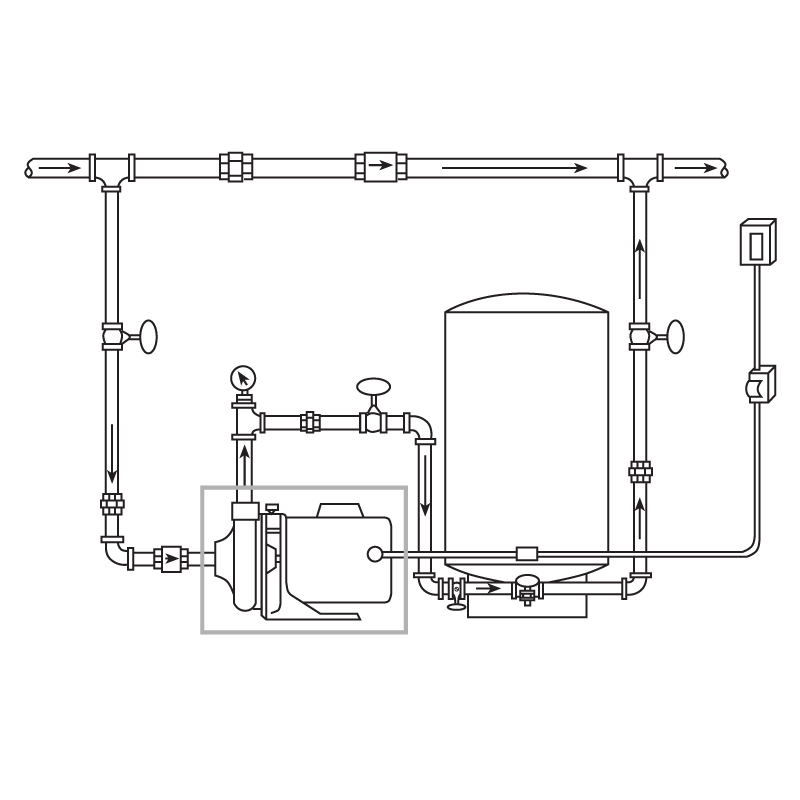

End Suction Centrifugal Pumps

End Suction Centrifugal Pumps

- High pressure, high head applications

- Vertical or horizontal split case

- Enclosed or open impeller designs

Applications

- Water circulation

- Liquid transfer

- Spraying systems

- Booster systems

Features

| Flow | up to 4,500 GPM |

| Head | up to 500 ft |

| HP Required | 1/2 - 7-1/2 HP |

| Pressure | up to 250 PSI |

Features & Benefits

End suction pumps come in a variety of sizes, materials of construction such as iron, bronze, stainless steel, or corrosion-resistant plastics, and impeller designs to handle everything from water to abrasive slurries.

- Vertical or horizontal mounting

- Close-coupled for minimal footprint

- Enclosed or open impeller designs

End suction centrifugal pumps often include one impeller and a volute type casing. Fluid enters on the suction end, moves along the vanes of the impeller, raising its velocity, and into the volute casing where the high velocity is converted into high pressure and discharged out the top.

This style typically features the casing, suction and discharge nozzles, all housed in a single chamber. However, when the casing is split along a vertical or horizontal plane in relation to the impeller, it is known as a split case pump. This type of casing design is preferred in higher flow applications where the impeller can be supported by bearings on both sides.

Product Resources

For General Information, Terms & Conditions, Performance Curves and Engineering Data, please reference our manufacturer’s resources.

Questions? We’re here to help

See Our ServicesSign Up for E-News

Get news on the latest promotions, events, resources and more!

"*" indicates required fields